- #Atlas copco serial communication protocol serial#

- #Atlas copco serial communication protocol software#

#Atlas copco serial communication protocol software#

Third-party software that performs data logging and facilitates programming tasks for Global 8 units can be found and downloaded here. Contact us to discuss your needs.Ĭompatible Battery-Powered Tools: Panasonic EYFLA4AR, EYFLA5AR, EYFLA5QR, EYFLA6JR * Other protocols may be made available by special order. Global 8 Controller with Ethernet card and ToolsNet

#Atlas copco serial communication protocol serial#

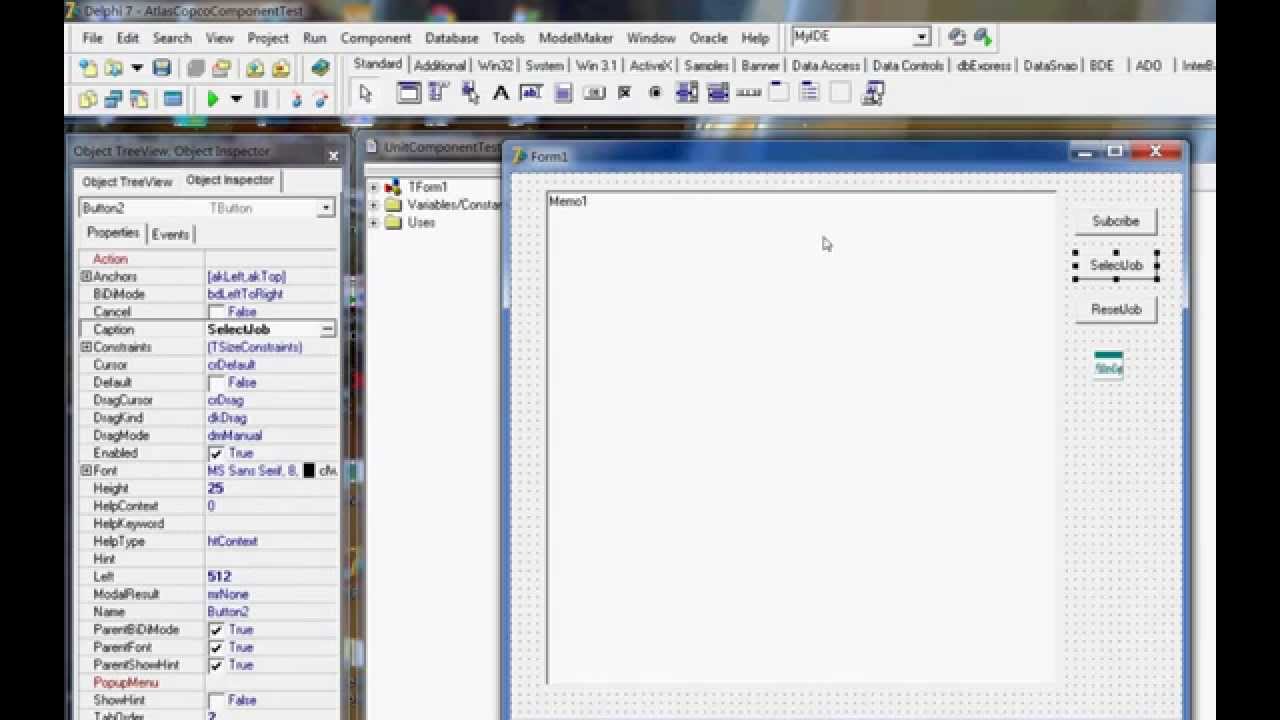

Global 8 Controller with Ethernet card and Ethernet IP 22 COMMUNICA TION / PROTOCOL COMMUNICATION Power Focus communicates by both Ethernet and Serial communication links and can tie in with ToolsTalk and. Global 8 Controller with Ethernet card and PFCS Global 8 Controller with Ethernet card and Atlas Copco® Open Protocol USB connector for computer communicationsġ4-character, 2-line Human-Machine Interface for Ethernet statusĩ-pin serial connectors for serial printerĩ-pin serial connectors for bar code readerĪtlas Copco Open Protocol & ToolsNet only

LED’s for Cycle Accept, Cycle Reject and Batch Acceptġ0-Pin I/O port for 24 VDC signals & relaysĢ.4 GHz RF communication distance up to 50’ (16m) Yes on all models (Battery tools excepted)Īccepts task sequencing from external commandsĭisplay shows current tool and current tightening status Manages & communicates attribute torque data Yes for all (1100-Series Exacta required)s Manages & communicates variable torque data Integrates 2.4 GHz Wireless Preset Torque Wrenches Integrates PST 1000 Pressure Sensor/Transceiver for Integrates 1100-Series Exacta® 2 Digital Torque Wrenches Maximum number of torque tools controlled in any combination When multiple tools of multiple types, or many tools of the same type must be used at a single cell or station, one of the Global 8-Ethernet family of controllers is likely the optimum controller for that location. The lower display and keypad in the image at right provide a Human-Machine Interface for programming elements of the communication.įurther, these units all have relays and a port for connection to your 24 VDC control system, and are capable of fixed or variable sequencing if desired.

Available protocols include: Atlas Copco Open Protocol, Ethernet IP, PFCS, and ToolsNet. The Global 8-Ethernet controllers all have Ethernet ports, and one of the four available communication protocols pre-installed at the factory. Global 8 controllers work with up to eight PST 1000-equipped ported pulse tools, 1100-Series Exacta® 2 digital torque wrenches, 2.4 GHz preset torque wrenches or select battery-powered tools* - in any combination.Ī large and readily-visible display assures the operator is always aware of the status of each tightening, the progress through each batch of fastenings, the correct tool for the currently-active fastener, and other information required to assure the fastening is properly performed. Global 8 Ethernet Torque Tool Controller Applications

0 kommentar(er)

0 kommentar(er)